RTL

Click to Enable

Cushion packaging is a critical protective material designed to safeguard fragile items during transit and storage. This packaging solution plays a pivotal role by cushioning items from impacts and shifts, ensuring that products reach their destinations in pristine condition.

The vital importance of cushion packaging in shipping cannot be overstated, as it contributes to efficient logistics, cost savings, and a positive customer experience.

Cushion packaging employs effective shock absorption techniques to safeguard items from abrupt impacts during transit. By incorporating materials such as air-filled plastics and foam, cushion packaging prevents the deformation and damage that can occur from unexpected drops or collisions. These materials provide a buffer that absorbs kinetic energy, minimizing the force transferred to the packaged item and thereby protecting it from harm.

Moreover, cushion packaging plays a crucial role in preventing vibration damage, thanks to its specially engineered materials. The design of these packaging solutions focuses on absorbing and dispersing vibrational forces, which can often lead to loosening components in electronics or causing cracks in fragile items. For instance, foam materials distribute vibrations across a wider area, reducing the risk of concentrated stress points.

Additionally, there is a range of material choices available in cushion packaging that enhances protection for various items. Air-filled plastics, like air pillows, are ideal for filling voids and preventing movement within packages. Meanwhile, foam materials offer excellent shock absorption and are particularly beneficial for heavier or more delicate goods. Each material offers distinct advantages, such as the lightweight nature and recyclability of air-filled solutions or the custom-fit protection offered by foam inserts, making them suitable for a variety of shipping needs.

When it comes to protecting your products, air pillows have become an essential tool across various industries. These small, lightweight, and inflatable pillows are excellent for filling voids in packages, preventing items from shifting during transit. They are favored for their space-saving nature, which reduces shipping costs and storage space requirements. Many businesses, from e-commerce to electronics, utilize air pillows for their ability to provide reliable cushioning for delicate items.

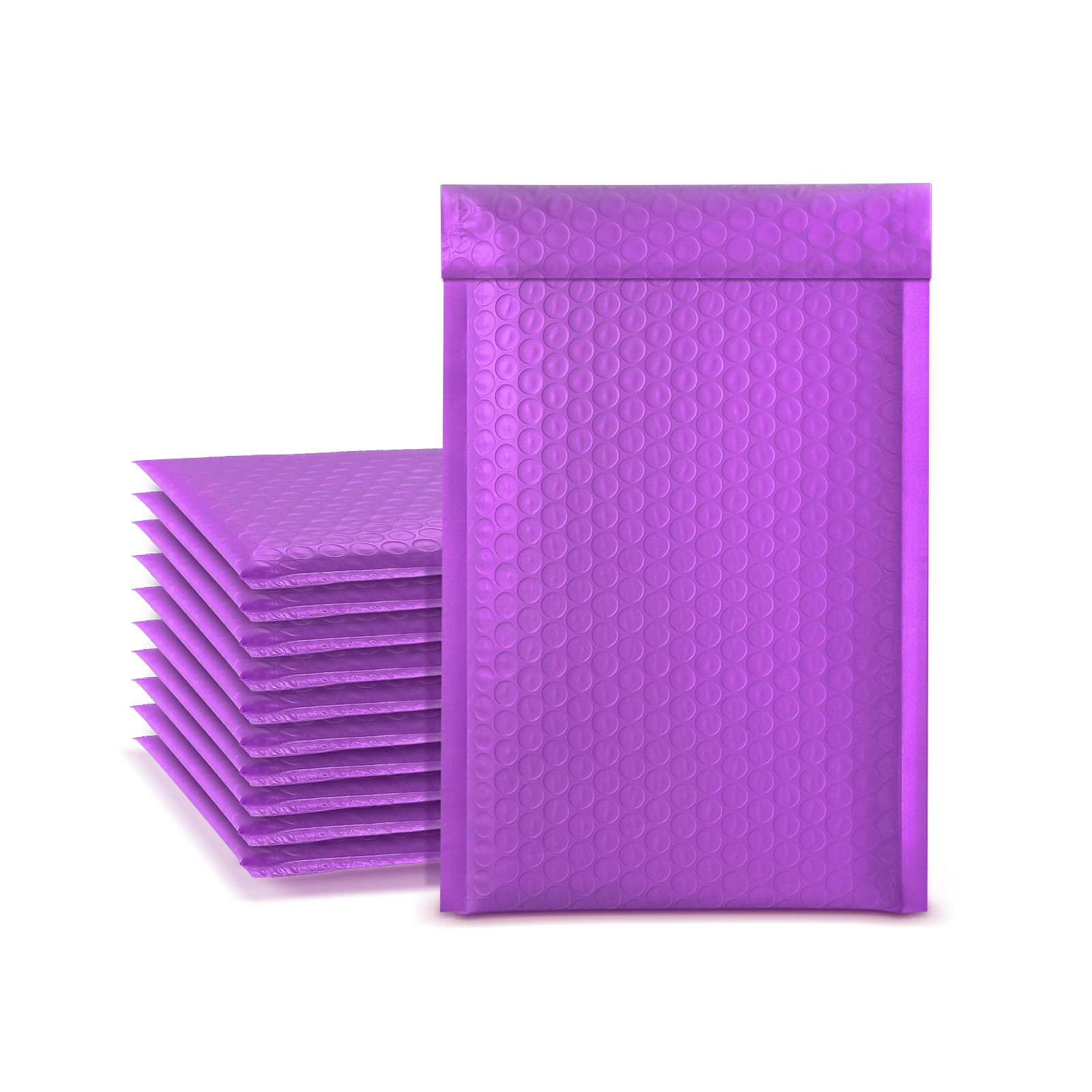

Bubble wrap remains a classic choice for cushion packaging due to its versatility and ease of use. This well-known material consists of plastic film sheets with air-filled bubbles that provide immediate shock absorption and protection from external forces. Its accessibility and efficiency make it suitable for a variety of packaging scenarios, whether it’s wrapping fragile items or layering for added protection. The convenience of inflating bubble wrap on-demand further enhances its utility in fast-paced packaging environments.

Inflatable packaging systems offer a modern twist on traditional methods by providing customized filling options and easier storage capabilities. These systems are particularly beneficial for businesses dealing with fragile or uniquely-shaped products. By allowing customized air-fill levels, inflatable packaging ensures items receive the specific cushioning they need, enhancing protection. Moreover, since they inflate only when needed, these systems save storage space and reduce material waste, making them an eco-friendly choice.

The cost-effectiveness of cushion packaging is a major advantage for businesses involved in shipping. Utilizing cushioning materials can lead to significant cost savings by reducing the risk of product damage during transit. For instance, companies report up to a 15% decrease in shipping damages, which translates to savings on product replacements and decreased return processing. This financial benefit highlights why many businesses are making this strategic choice.

Environmental considerations are becoming increasingly important in packaging materials, and cushion packaging is no exception. Many cushion packaging products are now made from recyclable and biodegradable materials. These eco-friendly options help businesses meet sustainability goals while adhering to consumer preferences for greener practices. This shift towards sustainable packaging solutions demonstrates a commitment to reducing environmental impact.

Cushion packaging is incredibly versatile, making it applicable across various industries. For example, the electronics industry uses it to protect sensitive components from shock, whereas the food industry benefits from its ability to secure perishable items. Such adaptability ensures that cushion packaging can meet diverse industry needs efficiently, providing custom solutions for different types of products.

Protective Air Cushion Packaging is an exceptional solution for securing fragile items during shipping. This product is specifically designed with a lightweight and durable bubble wrap that effectively cushions your goods against shocks and impacts. Ideal for shipping electronics, glassware, or any delicate items, it ensures optimal protection throughout the transit process. The eco-friendly and recyclable materials used in its construction also underscore its commitment to environmental sustainability.

Key features of this air cushion packaging include its lightweight design that aids in reducing shipping costs, ease of use in various shipping applications, and highly effective cushioning properties that ensure the safety of items during transit. These benefits make it an economical and reliable choice for businesses, enhancing customer satisfaction and protecting valuable goods efficiently. Customers should choose this air cushion packaging for its proven track record of protecting shipments. Leveraging testimonials from satisfied users and expert opinions further solidifies its reputation as a trustworthy packaging solution.

The cushion packaging industry is increasingly shifting towards sustainable materials as businesses adopt eco-friendly options. Many companies are replacing traditional plastics with biodegradable or recyclable materials to minimize their environmental footprint. This shift aligns with global sustainability goals and resonates with eco-conscious consumers.

Automated cushion packaging solutions have revolutionized efficiency in logistics. By employing machines that inflate and seal cushions, businesses can reduce labor costs while maintaining high-quality packaging standards. These systems not only save time but also ensure product consistency, thereby enhancing overall shipping reliability.

Looking ahead, the future of cushion technology is bright with ongoing research focused on enhancing performance and sustainability. Innovations such as advanced materials with improved shock absorption and energy-efficient inflation systems are on the horizon. As these technologies develop, they promise to offer safer and more sustainable packaging solutions for businesses worldwide.

Selecting the right material for cushioning fragile items is crucial to ensure their safety during transit. Consider the item's dimensions and fragility. For smaller, less fragile products, air pillows made from durable polyethylene are ideal due to their lightweight nature and ease of use. However, for more delicate or irregularly shaped items, such as collectibles or glassware, air bubble rolls can provide superior protection due to their ability to wrap securely around products.

Optimizing packaging processes is essential for enhancing efficiency while maintaining product safety. A checklist can be an effective tool to streamline operations:

Effective personnel training is vital to maximize the effectiveness of cushion packaging and minimize waste. Personnel should be educated on the correct selection and application of packaging materials, proper use of machines, and adherence to environmental disposal practices. This not only reduces waste but also ensures the safety and security of shipments, leading to increased customer satisfaction.